Ethanol is a $53 billion industry in the United States. Domestic demand has increased by more than 10% over the past five years — and exports have nearly tripled during that timeframe — pushing ethanol production to record heights. The market will continue to grow as gasoline blends with higher concentrations of ethanol begin to gain traction.

As one of the nation’s largest ethanol producers, White Energy has steadily increased its production capabilities. The company operates two state-of-the-art ethanol production facilities with the capacity to produce more than 250 million gallons of renewable biofuels a year. It distributes fuel to the world’s leading oil companies, both domestically and abroad.

The international market for ethanol is growing rapidly. White Energy exports ethanol to rapidly-growing markets in South America, the Middle East and India. Its ethanol plants have distilled spirits permits that enable the company to sell non-denatured ethanol into the international export market.

White Energy has invested $45 million in capital projects over the past five years to reduce production bottlenecks, enhance safety, and increase production capacity at its ICM-designed plants. The upgrades included new hammer mills and additional storage that increased production and the implementation of new technologies that improved ethanol recoveries and strengthened environmental protections.

Ethanol produced by White Energy enjoys low carbon intensity ratings, which is attractive to the growing West Coast market for low carbon fuels. California has a long-established marketplace for low carbon fuels, with new markets are continuing to develop in Oregon, Washington and Western Canada. White Energy will benefit from the continued growth in these markets.

About Ethanol

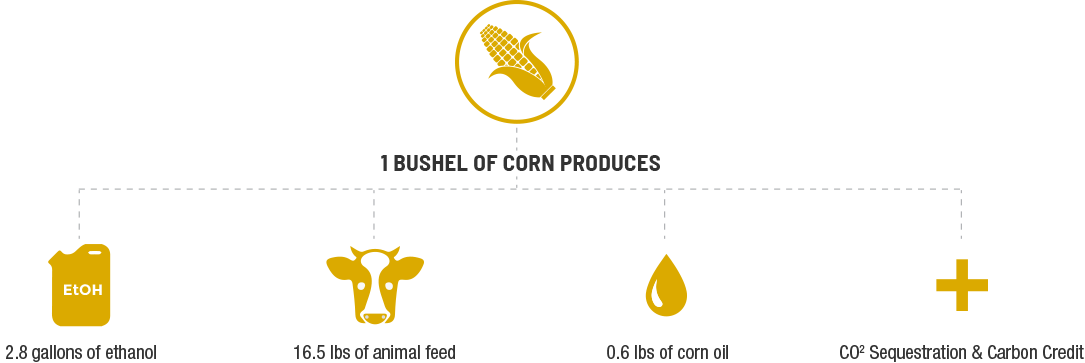

- Ethanol is a clean, renewable and high-performing biofuel made from sugars and starches found in grain.

- Virtually every gallon of U.S. gasoline today contains at least 10% ethanol, and gasoline with higher percentages of ethanol is becoming more common. Ethanol is a high-octane fuel that reduces the price of gasoline and remains one of the most effective tools for reducing harmful vehicle emissions.

- The U.S. is the world’s leading ethanol producer. Ethanol exports ranged from 1.4–1.7B gallons in recent years and double digit growth is expected to continue. Exports have increased by 425% since 2010.

WHERE WE MAKE ETHANOL

How We Make Ethanol

Like most ethanol plants, White Energy uses a dry milling process. It begins by grinding corn or milo kernels into meal that is then slurried with water to form a mash. Enzymes are added to the mash to convert starch to sugar. The mash is cooked, then cooled and transferred to fermenters. Once yeast is added, the conversion of sugar to alcohol begins. After fermentation, the resulting ethanol is separated from the remaining stillage. The ethanol is distilled and dehydrated, then blended with denaturant (such as natural gasoline) to render it undrinkable. The ethanol is then delivered by trucks and railcars to domestic and global markets.